Pouf mod. VINTAGE

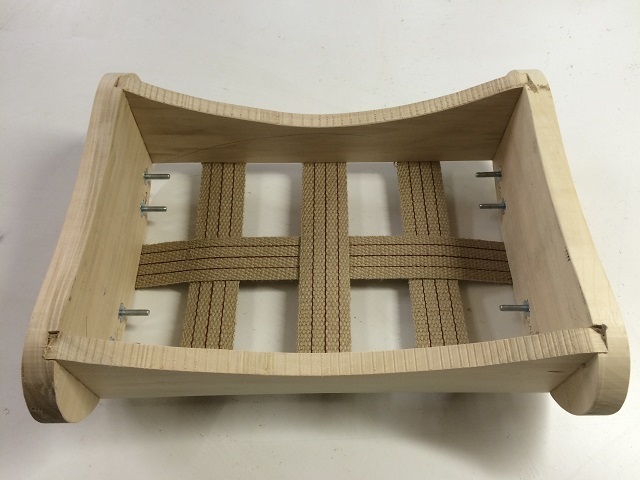

High quality structure made in solid poplar.

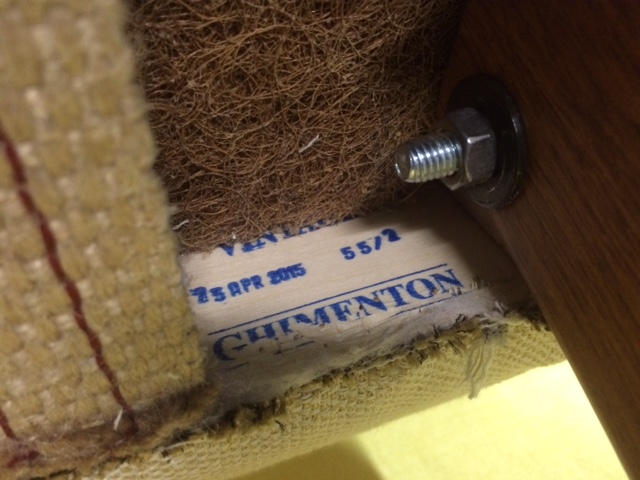

Feet in durmast wood (colour finish chosen by the Customer).

Padding with a double layer of belts, rigid at the bottom and elastic on top, entirely made with rubberized coconut fiber (without any use of "sponge rubber"). Surface finish in polyester fiber lining and cotton fabric.

Kind of cover chosen by the Customer (nailed, removable, nailed with housse, piping, trimmings, etc.).

Standard dimensions (changeable by the Customer): width cm. 55, depth cm. 50, height cm. 42

Example of pouf mod. VINTAGE, NAILED version (non-removable cover):

Chestnut colour finish for the feet (as requested by the Customer).

Nailed fabric cover (non-removable).

Dimensions: width cm. 55, depth cm. 50, height cm. 42

Price (excluding fabric cost): Euro 526 + VAT (shipping excluded)

Needed fabric: mt. 1 h.140 without pattern repeat as photos

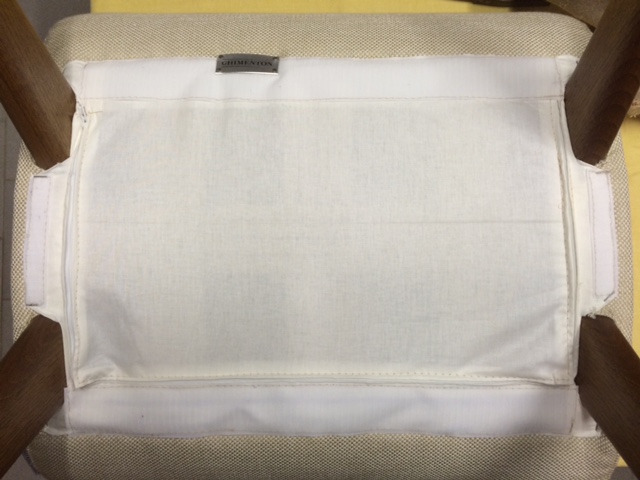

Example of pouf mod. VINTAGE, NAILED version (non-removable cover) with HOUSSE (protective removable fabric cover):

Chestnut colour finish for the feet (as requested by the Customer).

Nailed fabric cover (non-removable) + housse (protective removable fabric cover).

Dimensions: width cm. 55, depth cm. 50, height cm. 42

Price (excluding fabric cost): Euro 608 + VAT (shipping excluded)

Needed fabric for nailed cover: mt. 1 h.140 without pattern repeat

Needed fabric for housse: mt. 1 h.140 without pattern repeat as photos

Fabric washing instructions directly sewn on the housse:

Technical details:

High quality solid poplar structure:

Very strong fixing of feet:

Bottom layer of rigid jute belts:

Filling made entirely of rubberized coconut fiber:

The rubberized coconut is a material obtained from the fiber of coconut shell combined with natural latex. The coconut fiber is particularly resistant and does not deteriorate over time, even over decades; its structure allows optimum ventilation and breathability counteracting the accumulation of moisture and dust. In fact, the rubberized coconut is generally used in the production of mattresses, in particular for the nautical sector where the coconut fiber allows the ventilation of the mattress also when in contact with wooden panels that would otherwise create mold on the bottom of the mattress. The natural latex of which the coconut fiber is sprinkled serves to give elasticity and bind the material in a single body, which in fact comes in the form of slabs of various thicknesses:

Top layer of elastic belts:

The construction of sittings with a lower layer of rigid jute belts, filling entirely made of rubberized coconut fiber and an upper layer of elastic belts, is a specialty and characteristic of our productions. This new system is inspired by the principle of ancient sittings, made of knotted springs and hand-stitched horsehair, but updating it with simplified techniques that anyway guarantee, or perhaps even increase, the durability of the padding and keep it clean, avoiding the accumulation of dust inside the padding (which instead takes place in old vegetal or horsehair padding).

Additional surface layer of rubberized coconut fiber:

All the padding is manufactured without using anywhere the most common (and also cheaper) flexible polyurethane foam, also known by the term "sponge rubber". The flexible polyurethane foam, in fact, has the disadvantage of oxidizing in the long term (20-30 years) presenting the typical "chalking" (yellow powder) and to issue rubber smell after a few years old, especially if the product is placed in humid and little ventilated areas. The rubberized coconut fiber, instead, does not have these defects and even over 20-30 years of use it remains totally intact and odorless.

Surface finish in polyester fiber lining:

Final cover of the padding with cotton fabric.

While manufacturing the padding and the fabric covers, solutions are adopted in order to grant the access to the fixing bolts of wooden feet, making the operations of taking apart and reassembling them easy in case maintenances and wood polishing are needed:

Each item is cataloged and identified by a reference number, which characterizes it as a unique piece:

For every single item we manufacture we always make an extra “sample cover” (in both cases of removable cover version and fixed/nailed version) which is archived by us. So, even after many years and also for fully customized versions, we can always make new covers without taking back the armchair to our workshop (in versions with fixed/nailed cover, if it is not possible to bring back the armchair to our factory, the works of un-nailing the old fabric and nailing down the new fabric, sewn and pre-arranged by us, can be easily done by any local upholsterer). You cannot turn a version born with fixed/nailed cover into a removable cover version (or vice versa) without bringing back the sofa to our workshop (or at least it should be entrusted to a professional local upholsterer):